NORDHAVN 90

NORDHAHV 90 – 2012

NORDHAHV 90 – 2012 Information

Boat Type

NORDHAVN 90 2012 a vendre

Voici le superbe NORDHAVN 90 prêt pour son prochain propriétaire. NORDHAVN construit que des trawlers d’exception. Rien ne s’y compare. Celui-ci est particulièrement intéressant, son niveau de décoration, ses aménagements le rendent vraiment unique.

Les plus hauts standards sont bien sûr la marque de commerce de Nordhavn surtout pour la salle des moteurs. Vraiment spectaculaire comme fonctionnalité.

La cuisine gourmet va également vous étonner. Vraiment, le budget a été sans limites partout sur ce trawler.

Il est présentement localisé à Palm Beach (Floride), contactez-nous pour les détails au 514-521-1221

NORDHAVN 90 2012 for sale

Gorgeous, fully loaded 2012 Nordhavn 90 ready to take you anywhere in the world!

This Nordhavn was built for a very knowledgeable yachtsman to the highest standard.

From her beautiful custom Walnut interior to the incredible gourmet galley, no expense was spared during construction.

Maintained to the highest standard by her professional crew since new, this Nordhavn won’t disappoint.

This Nordhavn is located in Palm Beach, please contact us at 514-521-1221 for all details.

TECH SPEC :

- Builder: Pacific Asian Enterprises

Designer: Jeff Leishman

- Dimensions

- LOA: 90 ft 0 in

Beam: 24 ft 0 in

LWL: 77 ft 11 in

Maximum Draft: 7 ft 6 in

Displacement: 400000 lbs

- Engines

- Engine 1:

Engine Brand: MTU

Engine Model: Series 60

Engine/Fuel Type: Diesel

Engine Hours: 7500

Engine Power: 625 HP - Engine 2:

Engine Brand: MTU

Engine Model: Series 60

Engine Hours: 7500

Engine Power: 625 HP

- Tanks

- Fresh Water Tanks: Fiberglass (900 Gallons)

Fuel Tanks: Fiberglass (7000 Gallons)

Holding Tanks: Fiberglass (250 Gallons)

- Accommodations

- Number of cabins: 4

Number of heads: 7

|

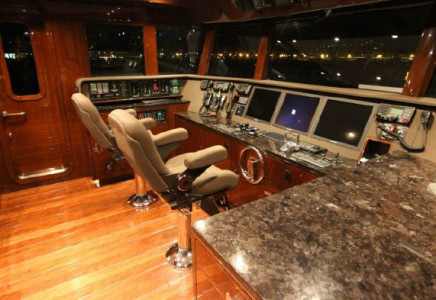

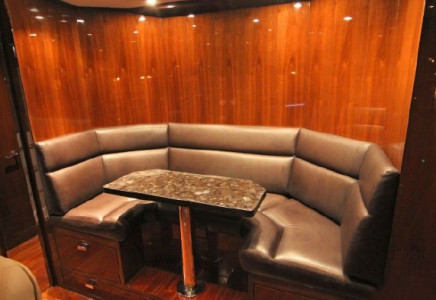

Specifications Walkthrough Entering the salon from the vast aft deck, you immediately notice the detail put into building “ZEMBRA”. Beautiful high gloss walnut throughout with custom stone floors and granite countertops. The salon is a spacious area, with couches on both port and starboard. The custom-built dining table is set to starboard and could seat up to eight. Forward to port is the custom gourmet galley with a divider to separate it from the salon/dining area. In the galley area there is also a pantry. To starboard is the day head and then moving forward down a couple of steps to the master stateroom with king size bed and the master head/shower area. The windows (6) in the master are mounted vertically rather than horizontally. Aft of the master are the steps down to the guest rooms, one forward with two single beds, head and shower, two aft VIP rooms with king size beds and en-suite heads and showers, as well as custom wall coverings. On the bridge level, you find a pilothouse which features a commanding view for navigating and is complimented with a full array of electronics, Stidd chairs, custom couch and table. Aft is a passageway leading to the “sky lounge” and bathroom. This area boasts a large couch to port and workout area with a stair master to starboard. There is also an office area with desk and lots of drawers. Forward of the “sky lounge” are the stairs to the flybridge featuring a custom walk thru sunbathing area, Jacuzzi, BBQ, and custom built-in settee. This area is a entertainer’s dream with its 360 degree panoramic view. Access to the engine room and crew quarters is from the port side deck with the engine room forward and crew cabin aft. The lazarette can also be accessed from the crew area. INTERIOR

Custom Features

Main Salon

Main Deck Day Head

Galley

Master Cabin

Master Head (His and Hers)

Pilothouse

Sky Lounge

Crew Cabin

Forward Port and Starboard Guest Cabins

Forward Guest Cabin

Flybridge

Engine Room

STANDARD MACHINERY Main Engines

Gear Box

Engine Instrument Panel

Engine Controls

Gear Box

Generator #1

Generator #2

Oil Change System

ABT System

AIR CONDITIONING SYSTEM AND VENTILATION SYSTEMS Air Conditioning System

Engine Room Ventilation System

FIRE PROTECTION SYSTEM

Lazarette:

STEERING SYSTEM

PLUMBING SYSTEM Water Tanks

Gray Water System

ELECTRICAL SYSTEM

Electrical Panels

EXTERIOR, DECK HARDWARE, and EQUIPMENT All horizontal surfaces on deck to have a diamond pattern non skid as shown in deck plan – standard non skid to be a contrasting color to parameter deck Carlisle & Finch 200 watt spotlight with dual station remote controls. Unit mounted on the flybridge hardtop.

ELECTRONICS:

Additional Equipment

|

Clause de non-responsabilité

Proprio-Bateau et Proprio-Yacht offrent les informations relatives à ce navire de bonne foi mais n’est pas en mesure de garantir l’exactitude de ces informations ni l’état du navire. Il revient à l’acheteur d’instruire ses agents ou ses experts afin de vérifier et de faire valider les informations de son choix. Ce navire est peut être offert sous réserve, il faut vérifier sa disponibilité. Ce bateau est peut-être offert en partenariat avec un autre courtier.

Disclaimer

The Company offers the details of this vessel in good faith but cannot guarantee or warrant the accuracy of this information nor warrant the condition of the vessel. A buyer should instruct his agents, or his surveyors, to investigate such details as the buyer desires validated. This vessel is offered subject to prior sale, price change, or withdrawal without notice. This boat may be listed in partnership with another broker.

Contact us regarding this Boat

Please call 514-521-1221 or you can fill out the form below and we'll get back to you shortly.

[contact-form 1'Contact form 1']